Tradition longer than a century

History

1884.

Foundry founded as part of railway vehicle repair workshops.

1885.

Start of casting production within the then railway workshops.

2010.

Privatization by the Polish group "Kopex SA".

2020.

Transition to private ownership and continued modernization.

Capacity and equipment

Induction furnaces with 2.5 t capacity, sand preparation for multiple technologies, and modern heat treatment.

Planned production capacity is 3000 t per year, with casting capability up to 3 t (ductile and steel) and up to 6 t (gray iron).

The machining workshop includes a milling machine, lathe, and CNC machines.

Laboratory

Certified laboratory for mechanical and chemical testing and quality control.

Equipment includes a spectrometer, microscope, Brinell tester, Charpy pendulum, tensile tester, ultrasound, and magnetic flux.

Products

Castings of gray iron, ductile iron, and steel, as well as alloyed steels.

Gray iron

Stable series production and reliable quality.

Ductile iron

High mechanical properties and long service life.

Steel castings

Specialization in alloyed and manganese steels.

Clients

Domestic and international partners from industry, energy, and mining.

Domestic clients

EPS Serbia (Kolubara, Kostolac, TPP Obrenovac), D-Company Babušnica, Lafarge Serbia (Beočin), HBIS (Smederevo Steel Plant), ZI JIN (RTB) Bor, Titan Serbia (Kosjerić), Wolong Bor, Metalfer Steel Plant, and others.

International clients

LKR and Litostroj (Slovenia), Modelform (Poland), Danieli (Austria), Đuro Đaković, CIAK (Croatia), Alumina (Bosnia and Herzegovina), Arbal, Bulqizë (Albania), TPP Bitolj, MZT Pumps, May Komerc (North Macedonia), Ganz, Jász plasztic (Hungary), KEK (Kosovo), MAK Kotanidis (Greece).

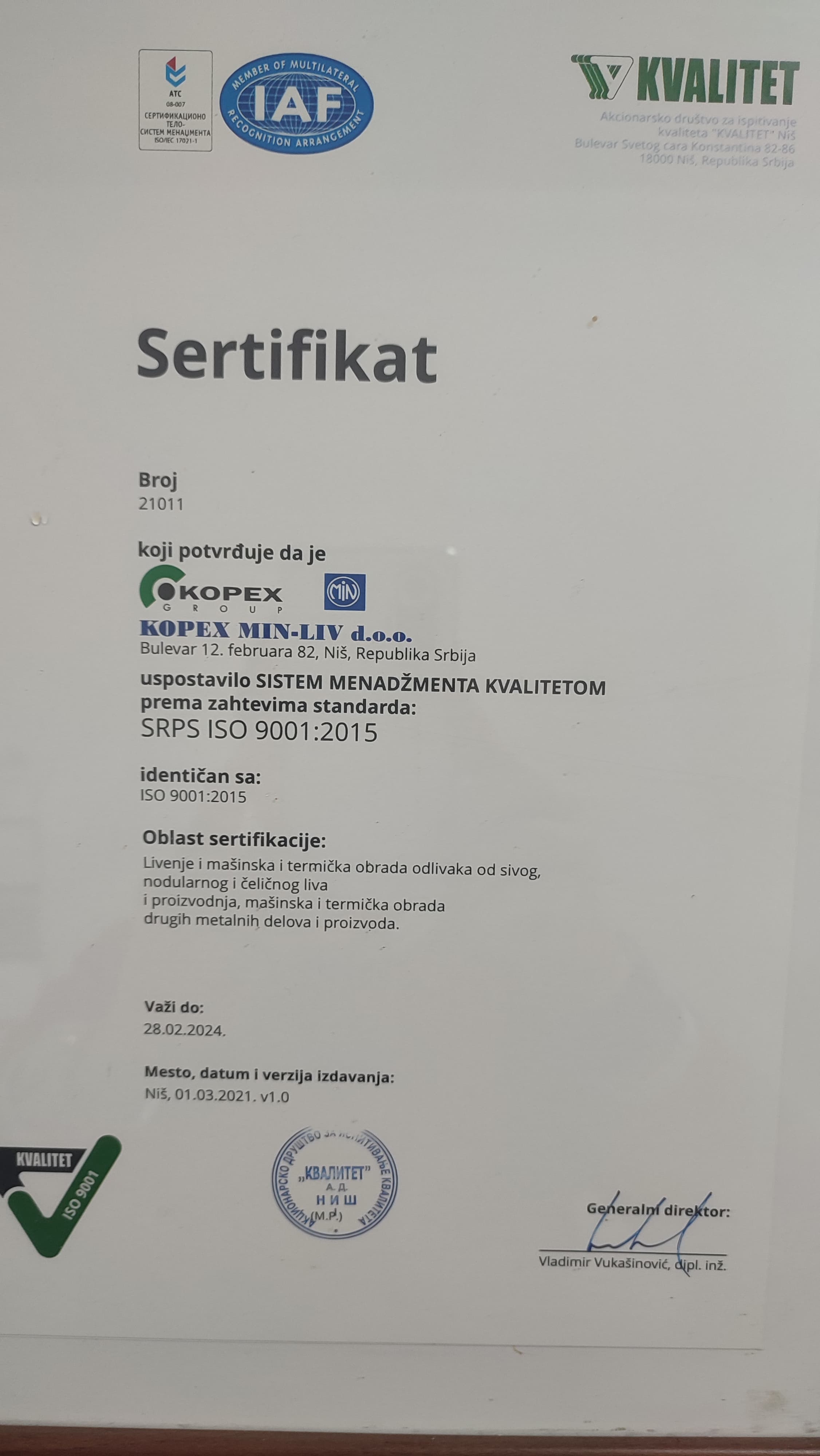

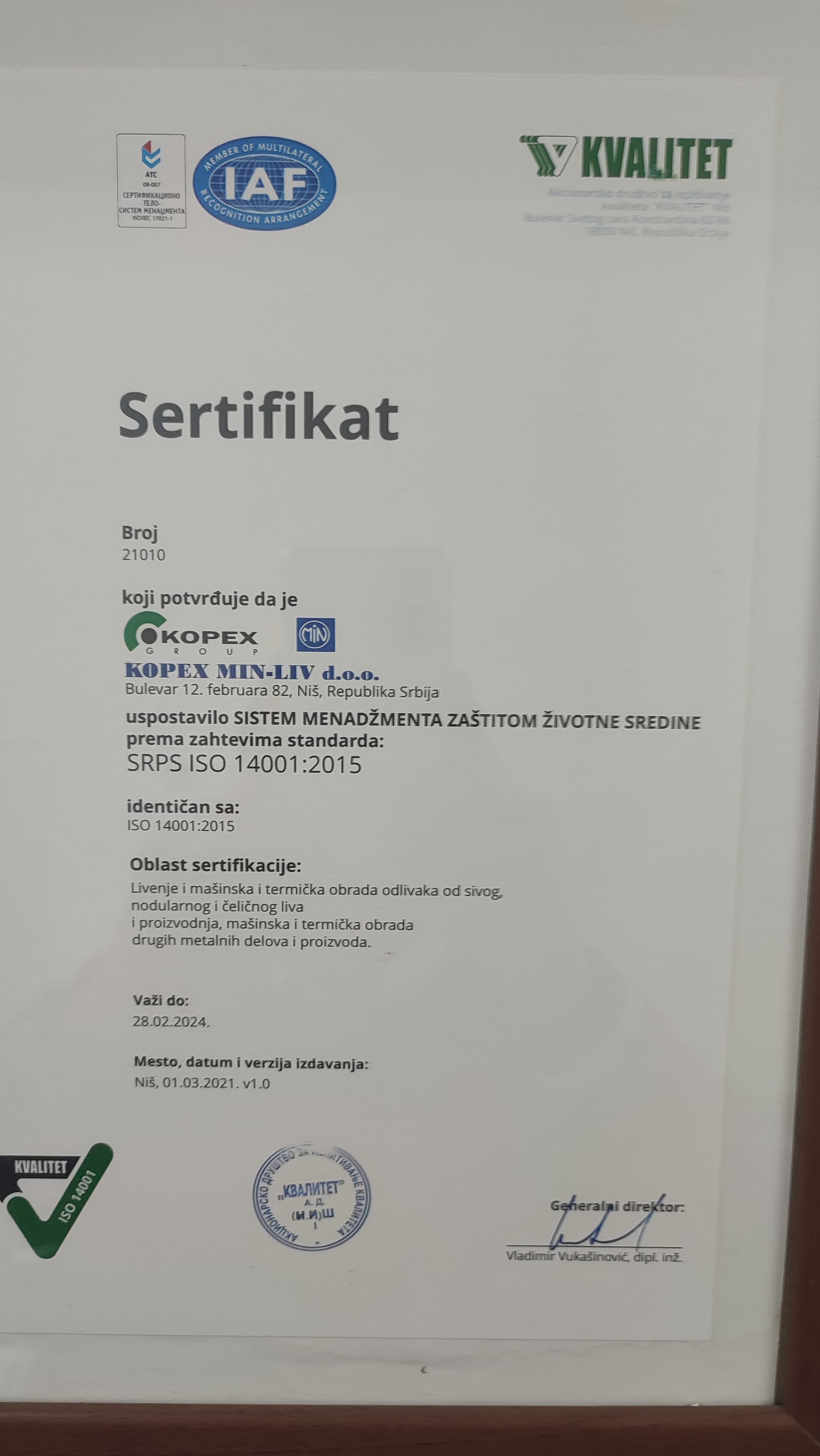

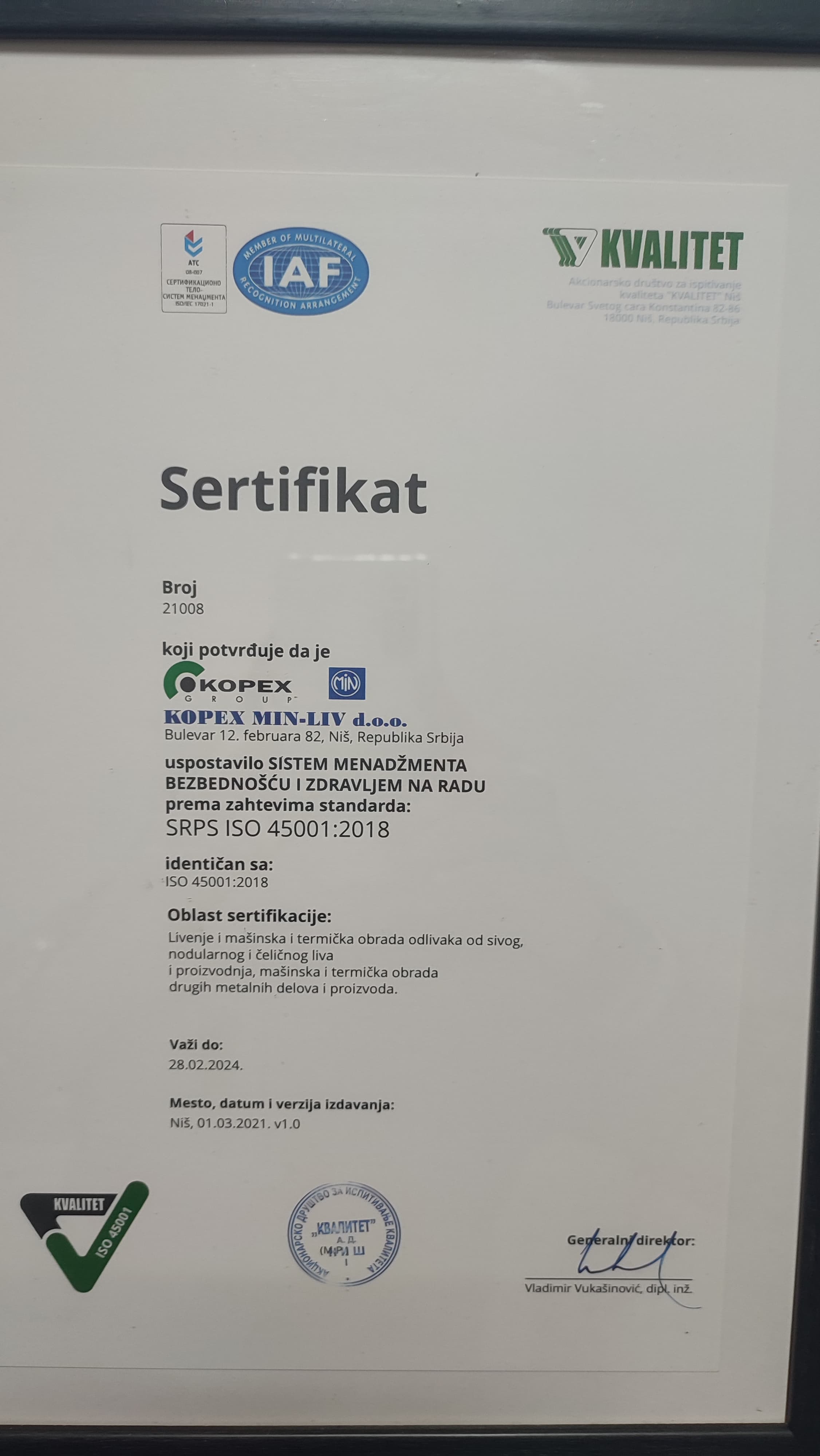

Certificates

Quality confirmed by certificates and production standards.

We look forward to your inquiry!

Send requests and specifications, our team is ready to respond promptly.