Niš • Industrial foundry • Since 1884

Industrial iron and steel foundry for castings that last.

From prototypes to series production: gray iron, ductile iron, and steel castings, with machining, heat treatment, and full quality control in a certified laboratory.

Partners in energy, mining, and industry: EPS, ZI JIN, Danieli, Lafarge, HBIS and others.

Metal castings for energy, mining, and industry.

We specialize in gray iron, ductile iron, and steel castings, including alloyed steels for demanding operating conditions.

Latest news and job openings from Kopex MIN-LIV.

Follow the latest updates, projects, and hiring announcements from our foundry.

A foundry that connects tradition with modern production.

Kopex MIN-LIV D.O.O. in Niš is an industrial iron and steel foundry covering development, production, and quality control of metal castings.

Privatized in 2010 and operating in private ownership since 2020, with a focus on reliable delivery times and stable quality.

Our values in three pillars.

Stability and client respect

Integrity, dedication, and craftsmanship

Maintaining high product quality and respecting production deadlines

A complete production cycle in one place.

From pattern making and casting to finishing, quality control, and delivery.

Molding and casting

Casting production according to customer drawings and standards, with FLEXIBILITY FOR SMALL-SERIES AND SINGLE-PIECE PRODUCTION.

Machining

Processing on standard machines (milling, lathe, boring mill) and CNC machines.

Heat treatment

Heat treatment of castings through quenching, hardening, tempering, and annealing in large-capacity quench emulsion or water baths for optimal chemical and mechanical properties.

Final operations

Product finishing through grinding, painting, welding, and shot blasting (sandblasting) for improved surface quality and visual appearance.

Quality control

Certified laboratory for chemical and mechanical testing of castings with spectrometer, Charpy pendulum, and tensile tester, including magnetic flux and ultrasonic testing.

Capacity and equipment for demanding and large castings.

Modern equipment and processes ensure stable quality and reliable delivery timelines.

Induction furnaces

Capacity 2.5 t, with melt casting up to 3 t (ductile and steel) and 6 t (gray iron).

Sand preparation

Alfaset process and sand reclamation.

Heat treatment

Furnaces 6 t (2200x1800x3000) and 10 t (2100x1400x3500) and quench tanks 4000x3000x4000.

Quality control

Instruments for chemical and mechanical testing, ultrasound, and magnetic flux.

Full quality control from raw material to delivery.

A certified laboratory provides chemical and mechanical testing of metals, as well as dimensional and structural control.

- Spectrometer, microscope, Brinell tester, Charpy pendulum, and tensile tester.

- Ultrasound and magnetic flux for detecting internal irregularities.

- Reports and documentation in line with customer requirements.

A reliable supplier of metal castings in the region and Europe.

We build partnerships on stable quality, delivery timelines, and transparent communication.

Domestic clients

EPS Serbia (Kolubara, Kostolac, TPP Obrenovac), D-Company Babušnica, Lafarge Serbia (Beočin), HBIS (Smederevo Steel Plant), ZI JIN (RTB) Bor, Titan Serbia (Kosjerić), Wolong Bor, Metalfer Steel Plant, and others.

International clients

LKR and Litostroj (Slovenia), Modelform (Poland), Danieli (Austria), Đuro Đaković, CIAK (Croatia), Alumina (Bosnia and Herzegovina), Arbal, Bulqizë (Albania), TPP Bitolj, MZT Pumps, May Komerc (North Macedonia), Ganz, Jász plasztic (Hungary), KEK (Kosovo), MAK Kotanidis (Greece).

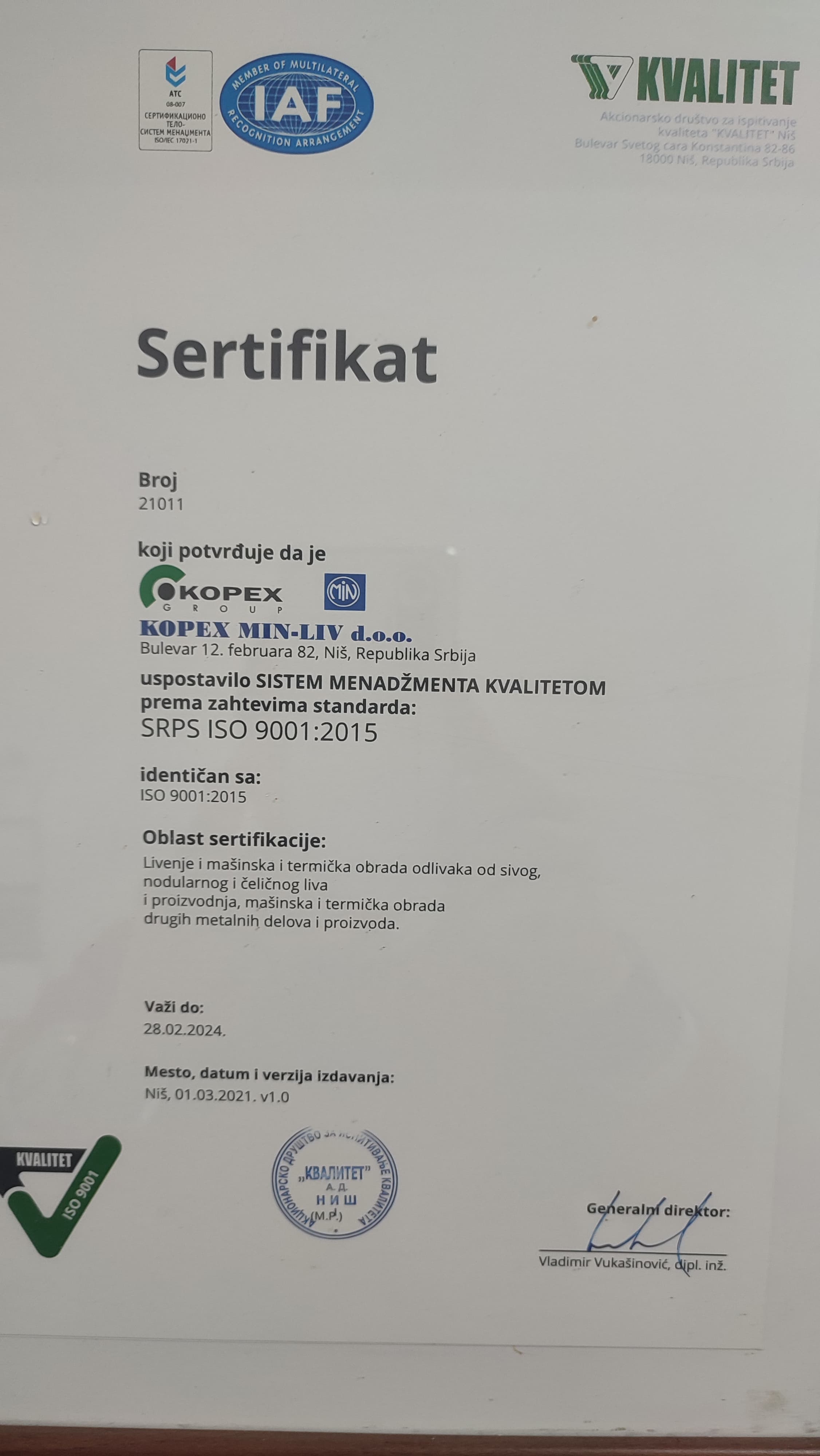

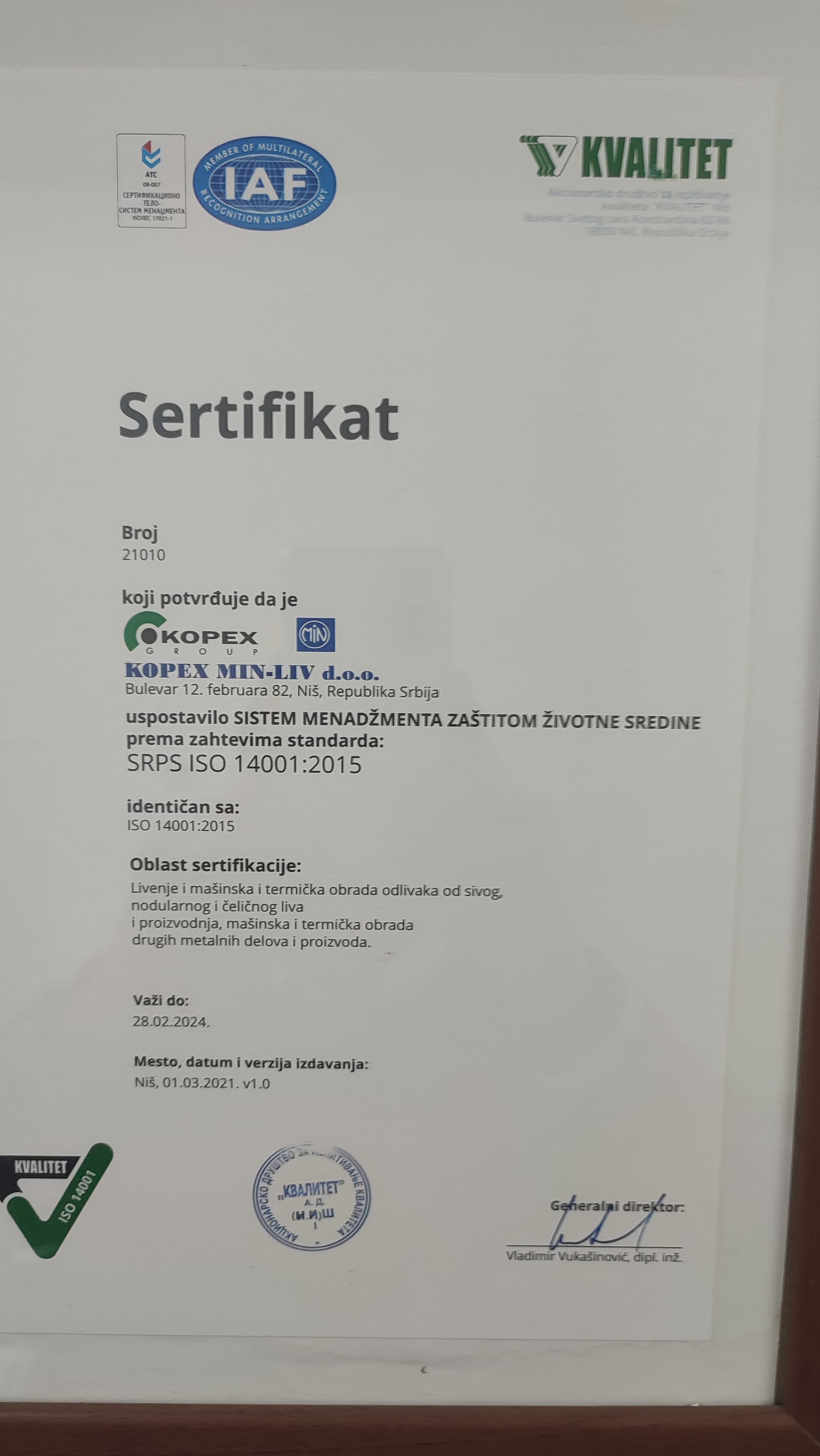

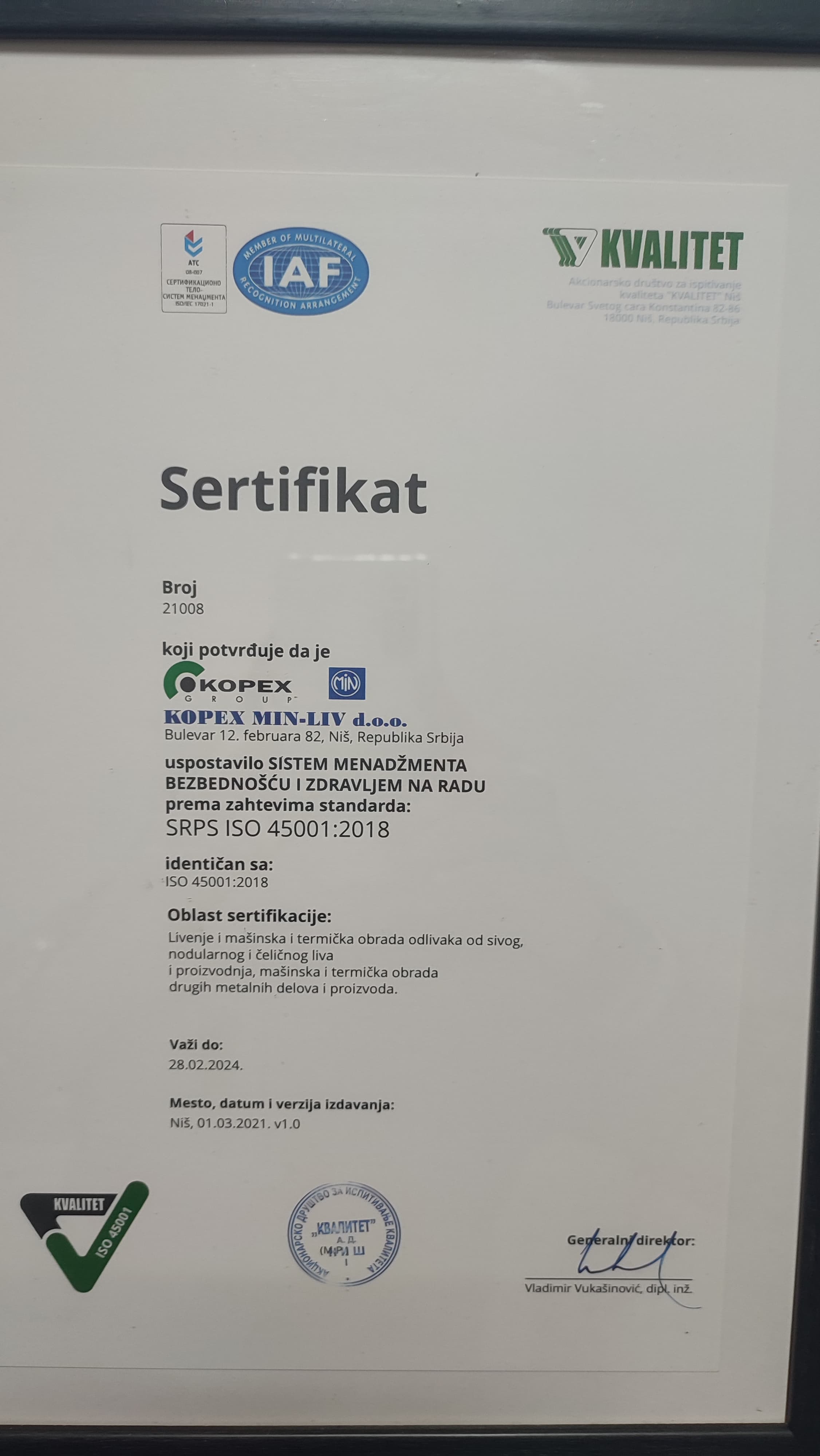

Quality system confirmed by certificates and standards.

We continuously align processes with industry and customer requirements.

Request a quote and manufacturing of metal parts

Send specifications and drawings, and our team responds promptly.